Branding/Logo

Gear ratios

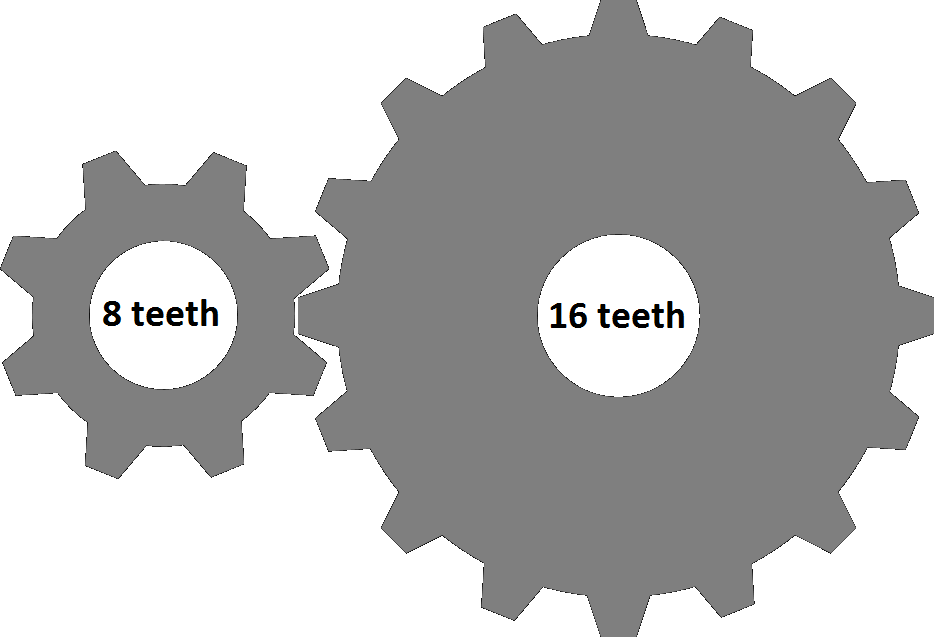

The amount of power generated by the wind turbine is directly varied with the amount of rotations the motor's axle makes per second as briefly mentioned above. The number of rotations is based on the torque that a wind turbine can generate. In order to maximise the amount of rotations based on torque one can use gears. Gears can increase the amount of rotations based on the ratio of the teeth on each gear. The greater the difference the more rotations. It is important to understand the larger the difference the more torque required to move the gears.

The gears above have a ratio of 1:2 ultimately doubling the voltage created if sufficient torque is provided.

Number of turbine blade

Turbine blades have an interesting and obvious relationship with power and ultimately voltage. The more blades there are on turbine the more torque can be created by the turbine but the slower it will rotate due to weight causing drag. Balance is also an issue regarding turbine blades. Theoretically, a single-bladed turbine would be most aerodynamically efficient but since balance is necessary for efficiency a minimum of 3 blades are normally required. Since four blades can be easily created with a single paper and since we were able to use multiple gears we decided to use four blades.

Blade angle must be 90 degrees

Based on our research in order to maximize the number of rotations your turbine makes per second and therefore the amount of energy you must maximise the amount of wind pushing against the turbine.An easy way to do this is to ensure that the turbine’s stand/frame allows it to point at the fan at a 90 degree angle; thus allowing the least amount of air to slip away from it.

Ensure balance within the turbine

A great way to do this by making sure each turbine blade is the same weight and size and that it is positioned in the right spot relative to the other blades. We did this simply creating all four blades with a pre-attached center thus achieving a perfect centre of balance from the get-go.

Ensure a rigid frame

Clearly when a turbine frame/stand is not sturdy and moves the turbine will produce less energy due to a loss of wind power. Hence, a strong frame is essential to an efficient turbine. An easy way to make a sturdy frame is by applying the same logic as if we were building a straw tower; rigid geometric forms create rigid frames. Hence, we used a triangle type frame which was glued to the base with a few stylish supports for extra safety assurance.

.png)

Ensure that materials are not defective

Throughout the process we checked nearly all of our materials such as straws and paper etc to ensure they were in top quality. We did this because defective materials are known to produce worst results.

Ensure minimal friction among axle and axle holder

Friction slows down the turbine’s rotation. Hence to have a fast moving turbine one must ensure that the friction against the axle (in our case a straw) must be minimal. Correct measurements and sizing are a good way to minimize this form of friction.

Plan construction and design ahead

In order to ensure that materials aren’t wasted and that the wind turbine created reaches the assigned goal to the best of its ability, planning is necessary.

Ensure that gears mesh properly

Often times due to some misalignment of the motor and axle the gears of a wind turbine will not mesh properly and will skip pegs. This is energy lost. To ensure this does not happened we measured and positioned out motor such that slight disturbances will not cause this problem.

Ensure the structure is manufactured as planned

Essentially this means it is important to stay focused throughout the construction of the turbine as often human faults cause a turbine to fail.

Check out our menu to learn more