.png)

The materials were rather restrictive as they had to be 100% recycled beside the materials provided by Mr. Hughes. Hence, the way in which we used the materials was very important; this is discussed in the research section. Only the brief use of each respective material is listed in the table. All materials had to be approved by Mr. Hughes.

| Item number | Quantity | Description/Use | Material |

|---|---|---|---|

| 1 | 1 | Small device that transforms the kinetic energy in form of rotatio from the turbine into volts (electricity).n | Motor |

| 2 | 2 | Various sized gears used to increase the motor axle's amount of rotations per second. | Gears |

| 3 | 1 | Length of plastic marked with intervals used for measuring the various building materials and structures. | Measuring tape/ruler |

| 4 | 1 | Tool used to cut wood and tape. | Sissors/saw |

| 5 | 2 | Used to make the wind turbine frame. | Lengths of Balsa wood |

| 6 | 1 | Used as an axle for the turbine to spin on. | Dowel |

| 7 | 1 | Used as an axle for the turbine to spin on. | Straw |

| 8 | 1 | Used to stop the turbine from moving back on the axle from the wind pressure. | Elastic |

| 9 | 1 | Used to construct the turbine. | Construction Paper |

| 10 | As much as needed | Used to attach materials together. | Tape + Glue gun |

| 11 | 1 | Used to allow the turbine to have a free-standing base. | Slab of Wood |

| 12 | 1 | Used to add stylish designs. | Sharpie |

Method + Challenges

After finalizing the concept of our wind turbine we spent hours in harsh labour perfecting our creation in order to achieve maximum efficiency. Here are some of the challenges we faced and how we approached solving them.

As a result of our plank of wood being used multiple times it was unbalanced due to a mat of dried glue being stuck on the bottom. We had to solve this alarming issue by scraping it off with a knife whilst being careful not to hurt ourselves.

There were some issues surrounding our motor moving out of position when the gears were spinning as a result of the glue being too soft. We solved this issue by adding extra support with tape to keep the motor in place.

Another issue was regarding the turbine moving inside of the straw axle holder. We had made cuts to allow it to fit in but it turned out that these acts caused the straw to be too big and allowed the turbine to much moving space. We solved this issue by simply using a new straw and fitting it in the hole in our frame using more careful methods.

Testing Process:

| Test Number | Voltage Acheived | Problem/Modification |

|---|---|---|

| 1 | To inconsistent to measure | Issues with turbine moving as a result of wind pressure. Elastic added on axle to stabilize. |

| 2 | 0.1 volts | Gears not meshing correctly. Measurements checked and motor repositioned |

| 3 | 0.3 volts | Overall frame slightly unstable causing external movement. Small supports added on both sides of frame. |

| 4 | 0.4 volts | Wind turbine exceeded expectations. Distance from fan optimized for maximum efficiency. |

| 5 | 0.6 volts | Solid. 4++ voltage achieved. |

Results:

Our wind turbine managed to exceed the set expectations achieving the 4++ level voltage. Obviously, this in of itself combined with the fact that we have provided research to why this is the case exemplifies why we effectively created a solution with the resources given. However, given that we did not score the highest voltage in the class with 0.6 volts there are several things we can look to improve upon. In the end our wind turbine exceeded the expectations we had set for it, and self-reflection is more important to us than being the best.

Isometric Sketch

.png)

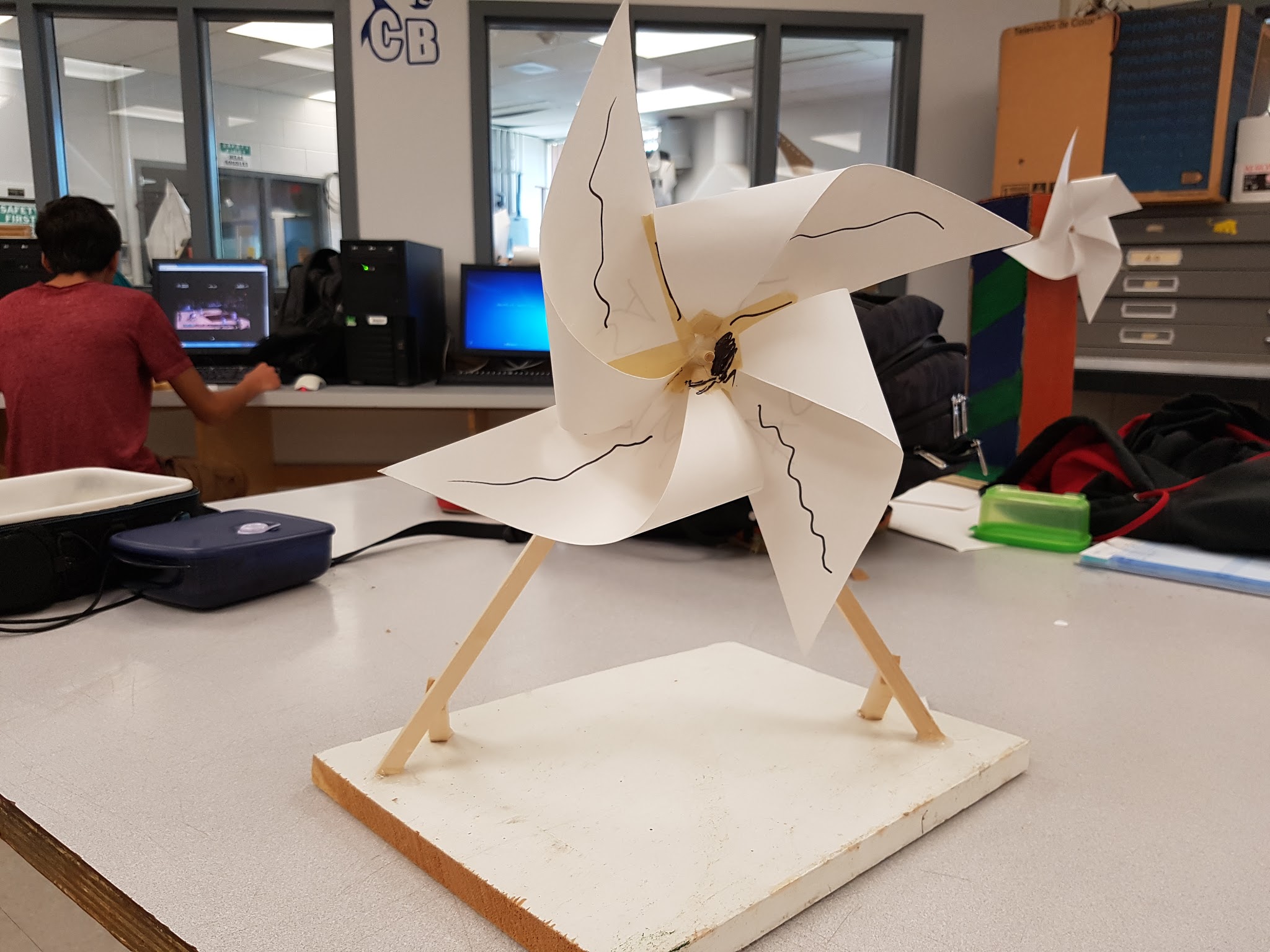

Picture

Dimensions

The following are the measurements we conducted after creating our wind turbine. They resemble our pre-planned measurements nearly exactly and hence we will not post those.

| Figure | Side Length 1 | Side length 2 | Height | Angle comparative to board (in degrees) |

|---|---|---|---|---|

| Base | 15cm | 13cm | 1.5cm | 0 |

| Frame Leg(s) | 2cm | 2cm | 12cm | 65 |

| Axle | 0.25cm | 0.25cm | 10cm | 180 |

| Turbine+Motor | 6cm | 6cm | 10cm | 90 |

Check out our menu to learn more